Challenge

Before it gets to our households, water must be first treated to meet drinking water standards. Water supplies must go through purification and disinfection processes to change from ground water into tap water. Water treatment plants must operate smoothly to provide undisturbed supply of water to our home, school, office, etc. The water treatment plant delivering daily almost 400 000 m³ of drinking water to one of the biggest cities in Poland wanted to eliminate a single, troublesome point of failure in their water treatment installation. In that system, water was treated with chlorine as a disinfectant to make it safe for public consumption. But to make water safe, chlorine must be first safely and precisely added to water supply and at this point we were asked to find the best possible way to convey chlorine, gaseous and liquid, from tanks into the system. Our goal was to provide a chlorine hose assembly of improved quality, to reduce equipment and maintenance costs.

Solution

In dry environment, with no moisture present, chlorine is considered as non-corrosive, but these properties change drastically in the presence of moisture, even all-present atmospheric moisture. Then it becomes extremely oxidizing agent. The majority of chemicals can be safely transferred by steel braided hoses yet not chlorine. Chlorine, especially in contact with moist is potentially aggressive to stainless steel. One may try to prevent this corrosive impact and may be successful but not in a water treatment plant. There, only a special chlorine hose can be used. The best of chlorine transfer hoses is PTFE tube with Hastelloy wire braid. The PTFE tube resists almost all chemicals, can be used to transfer reactive and corrosive chemicals, chlorine as well. Unaffected by chemicals it can operate in a wide temperature range, however since a complete hose assembly is considered, the working temperature is additionally limited by the working temperature of the Hastelloy braid and its fittings, which is 60°C maximum. In the case of such applications, the higher the temperature, the more corrosive is the environment. Even such alloys as Hasteloy are at risk of trace quantities of chlorine halogens diffusing through the PTFE tube and attacking the braid material. Fortunately, in this case working temperature is the same as ambient, it ranges from 5°C up to 35°C so chlorine transfer hose in Hasteloy braid withstands in the conditions where steel braided hose will undoubtedly fail.

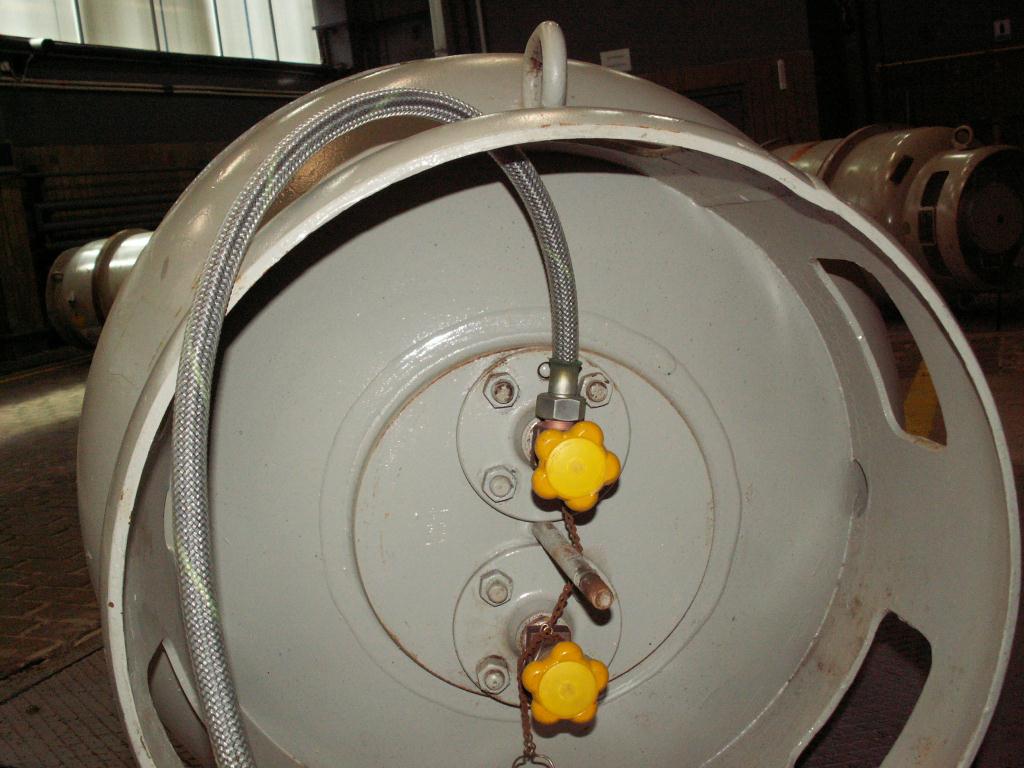

To produce a complete hose assembly, we used 1/2″ chlorine transfer hose 2,5m long with 1″ female thread fittings at both ends, conforming to DIN 477-1 standard for gas cylinder connectors. Both fittings and ferrules were made of Monel, another alloy resistant to chemicals. The hose assembly connected a chlorine one-ton tank to the pipeline of water treatment installation. The chlorine tank was set on a platform scale designed for weighing and thus monitoring feed rate of process chemicals. Properly mounted to the valves, the chlorine transfer hose assembly was ready for use at working pressure ranging up to the maximum of 10,5 bar.

Result

Durability is critical for all processes involving chemicals, aggressive chemicals in particular. The chlorine transfer hose assembly that we introduced greatly reduced the chance of chlorine leaks. Regular maintenance and inspections show that the assembly displays no corrosion or degradation. The service life of chlorine transfer hose and connectors made of adequate alloys is not determined by frequent leaks any more. In addition to the economic benefits, we added some quality and safety as well.