Challenge

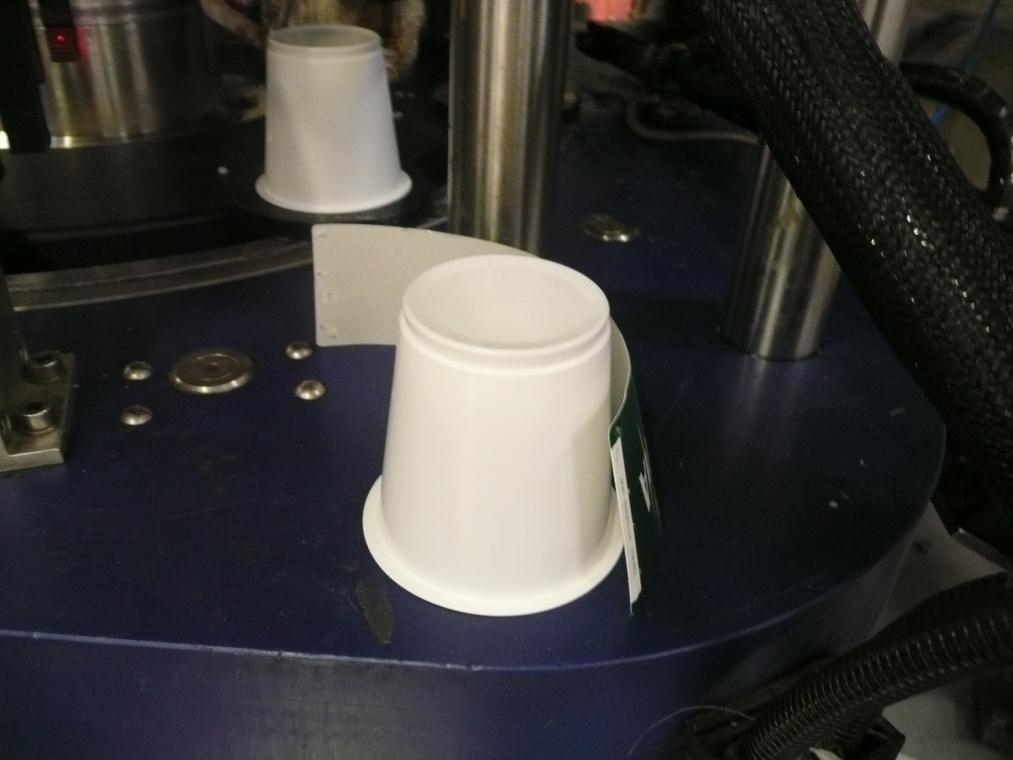

An electrically heated hose is the key element of an adhesive application system. Adhesive is transferred through the hose and then applied on a product. The failure of one electrically heated hose causes dozens of hours or even days of downtime. This problem was faced by our customer – a company providing packaging solutions for food industry. A faulty electric hose operated in a machine that binds cardboard wrappers on plastic cups. When it broke down, we were asked to find a more reliable electric hose assembly.

Solution

We selected the premium quality electric hose that effectively resists mechanical and thermal loads therefore best suits the application. The most important part of an electrical hose assembly is a core hose, where adhesive goes through. To ensure highest level of transfer, we decided to provide a glue hose with a Teflon (PTFE) hose as a core – a durable and effective solution. The PTFE hoses guarantee resistance to a whole range of chemicals, solvents or acids. Moreover, unaffected by almost all chemicals PTFE hose is also non-porous and non-sticky so the medium in it does not adhere easily to the hose walls. It can be successfully used to transfer hot glue. The working temperature of this heated hose was 200°C, adjusted to suit the temperature of glue conveyed in this application (180°C). A heating sensor, type NI 120, is crucial for any application conveying adhesives as its readings decide not only on temperature but also on viscosity of glue. The sensor must also instantly response to changes of ambient temperature. The hot melt hose was reinforced with stainless steel braid for resistance to pressure, bending and heat. The working pressure of the glue hose was 4 bar. It had an external cover made of black, wear-resistant polyamide to provide resistance to abrasion.

Result

The electrical hose we provided successfully operates applying hot adhesive on cardboard wraps. It ensures excellent thermal efficiency, consistent flow rates and improved wear-resistance. It proves to be more durable and reliable. Downtime is significantly reduced.

Your hose expert